How Does the Dairy Win?

David A. Domina's opening statement at trial.

No dairy farmer wants to go to court. This is true for many reasons. First, the process of being in court makes it difficult to focus on the dairy. Distractions can cost money.

Second, the trial process itself comes at the end of a marathon of work by the lawyers preceding it. Expert witness are needed. Documents are shared. The process takes time and energy.

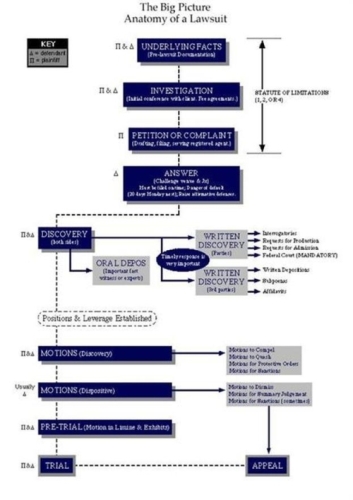

Third, cases move through courts in complicated ways. Some of this mystery is unraveled by the chart that appears on the page that follows. More is unraveled by the opening statement, given in a dairy case, that follows the chart, below. The opening statement provides a clear view of the fact that, once the case is in court, it is all about matters familiar to the dairyman, and comfortable to talk about with anyone.

Like all things that require much work, once all the advance effort has been invested and the trial day arrives, the important work of high quality preparation and thoughtful presentation are combined with awareness of human understanding and persuasion.

If the dairy is seeking to recover money, it has the burden of proving its case. Evenly divided evidence means the dairy loses.

As the party with the burden of proof, the dairy’s lawyer gives the first opening statement. Studies show 80% of civil jurors vote at the end of a case the way they would vote, if they could, at the end of the opening statement.

The jurors’ minds are never more open than when the opening statement is given. The opening statement tells the case’s story. The account below illustrates how important an opening statement can be. This case settled after the opening statement was delivered.

The Case of the Failed Rotary DairyOpening Statement by Mr. Domina

(Names, Places, Changed)

(Abbreviated Version)

Ladies and Gentlemen,

When Greg and Harold Lokial moved to the United States from the Netherlands, they chose Nebraska as Greg’s new home. This is a dairy family. For generations, the Lokials have been dairy farmers in the Netherlands. In the late 1980s, Harold moved to Manitoba, in Canada, about straight north of Grand Forks, North Dakota, a couple hundred miles. Then, the Lokials became Canadian dairy farmers, too.

By 1995, Greg, and his sister Meg, were out of high school, and ready to undertake their adult lives. They both chose dairy farming. Meg’s job would be to travel between the operations in the Netherlands and Manitoba. Greg would find a new spot.

This is an adventuresome family. They did not just buy the next farm. They looked for a new opportunity. First, this meant North America. Then, after establishing a small dairy of several hundred cows, but not 1,000, they decided to make an opportunity in the United States, and chose our state, Nebraska, as the place.

Many of you may have never heard of Anthon, Nebraska – a little settlement, really – a village of 60 people in Soldier County, between Mandan and Amarillo. Anthon was, in the beginning, a “jerkwater” along the railroad, like so many of our Nebraska communities.

The Lokials bought land south of Anthon – unimproved farmland – procured the necessary permits, conducted an investigation, and contracted to build one of the largest dairies in the state – a facility that would milk more than 1,500 cows per day.

The Lokials did not get established and stay in business in Europe through two World Wars without being inventive people. And they did not venture to Manitoba and establish a small dairy in a harsh place, amidst wolves and other risks of the northern plains, without perseverance. Their adventuresome, perseverant attitudes made them decide, in Nebraska, they would try a new technology – one emerging in Europe, originating, perhaps, in Australia, but at the time largely unknown in the United States.

The Carousel or Rotary Dairy

The technology involves a carousel.

Yes, a carousel – sort of like the carousel at the state fair – the one with the horses and other objects for children to ride upon, a merry-go-round if you will.

The Lokials knew of Pulsation Int’l. It is a German company, well-known in the United States, and certainly equally well-known in Europe and elsewhere in the world where cows are milked.

Pulsation Int’l is a leading manufacturer of milking machines and milking equipment. It may be the largest, or perhaps the second largest, milking machine company on the planet. Pulsation Int’l developed the rotary dairy, or the carousel for milking cows. It works like this:

A large, heavy platform is built on a rotating base, operated by electricity. Stanchions are built on the carousel.

Cows walk onto the carousel as it rotates slowly, into a stanchion, and as the machine rotates, they are milked. When they get back to the entrance point, the cow is gently nudged to exit by stepping backwards out of the stall. It is replaced, as the carousel moves a few more feet to the entrance point, by a replacement cow.

This process permits continuous milking. In the Lokials’ case, approximately 60 cows could be placed on the carousel at a time. And, as one finished the rotation and stepped off, a new one replaced it, permitting continuous milking so, as the carousel rotated, each cow would remain on it for one revolution and be milked. After a complete revolution, all cows on the carousel would be milked and replaced one-by-one. As one finished, another entered and commenced milking. As the carousel rotated and the cows finished milking, they were prepared to exit, did so, and were replaced with an unmilked animal.

Pulsation Int’l advertised the carousel program extensively. It wanted badly to establish this new milking method, and itself – Pulsation Int’l – as the leader in the industry in the United States. The Lokials know, now, their decision to do business with Pulsation Int’l and install its rotary milking equipment, made them the second dairy in America with the rotary system. The first is believed to have been in Idaho.

Of course, construction of a new building site, a new business, and a whole new type of business, was exciting for Anthon, Soldier County, and the Lokials. As you will learn from the evidence, it was exciting for Pulsation Int’l’s dealers and North America representatives, too. They were doing something new.

The Lokials did not know, however, that what was undertaken remained largely experimental and the experimentation was at their expense.

The carousel went in. Construction problems were dealt with as they occurred. The construction process was completed and milking began.

High quality cows were selected. The Lokials know cows. They chose Holstein animals with good genetics and great milking potential. They developed and implemented their plan for a 1,500 cow dairy. A dairy of that size requires approximately 1,800 animals since at any one time about one-sixth of the cows will be within 160 days of calving and be in their “dry cow” or non-milking period.

Things Did Not Work Out

Unfortunately, things did not work out in the milking process. The cows did not do well. Milk production never achieved reasonable or profitable levels. The machinery did not work as it should, diseases spread among the herd, including especially mastitis – something I suspect you all know about one way or another. Mastitis is a bacteria-based disease involving a staph infection of the mammary gland. It tends to occur because the mammary gland is not fully milked out, and milk that should be withdrawn from the gland remains within it.

These health problems and operating problems were battled by the Lokials. They did their best. The Lokials used high quality employees, excellent veterinary services, advice from good nutritionists, and did all the things a responsible dairyman should do, including those unique to a new location, and a newly assembled herd. But things did not work out, and the Lokials had some ideas about why.

It did not take long before these folks began to appreciate, as they watched their cows on the platform of the dairy, that Pulsation Int’l had made some serious miscalculations with its equipment. Eventually, the Lokials contacted me for help. They did so because their communications with Pulsation Int’l to try to solve the problem led to no success.

As you know from the jury selection process, I grew up on a dairy farm in northeast Nebraska. Milk cows were as basic to me as a kid, as was baseball – and when I was a kid, baseball was our sport of choice, not football or basketball or soccer as are more popular now, and in this community. “Cows were us” – but certainly we did not know cows like the Lokials do.

So, I was interested in joining the Lokials at the dairy and observing it. What an interesting place it is as you will see from the evidence. Cows, themselves, are fascinating animals. Docile, pretty, and productive of basic foodstuff, it is very hard not to like a dairy cow.

Dairy farmers, who work with gentle, pleasant animals, manage their reproductive cycles, and withdraw milk from their bodies tend to be soft-spoken, kind, non-litigious people. It did not take long for me to learn that the Lokials are these kinds of folks.

It also will not take long for you to see, as the Lokials saw that their dairy did not function as it should have. There were some basic, basic mistakes. You will hear the defense lawyer talk about them in a few minutes. The milking machine itself – the claw that affixes to the utter – looks like this [holding up claw]. These are the teat cups that fit on the cow’s teats and pulsate through a rhythm to withdraw the milk. Before they are placed, the utter and teats are washed and sanitized. After milking, another sanitation process is gently applied with warm fluid.

The milk passes through a milk line to a receiver which pumps it in a rotary dairy through a piping system to a milk tank where it is cooled. That is the milk flow.

Vacuum

To make the system work, a vacuum process must be used with vacuum pumps that create a negative pressure or vacuum to allow the milk to be withdrawn from the utter, and moved to its destination. Without vacuum, and a balanced vacuum system, a milking machine will not work.

The vacuum must be combined with electrical impulses to provide pulsation inside the teat cup through a plastic or rubberized liner, like this, that pulsates, replacing, artificially, the natural action of a calf’s process of suckling the mother. It also replaces the classic hand of the young farm boy who learns how to milk the gentlest cow in the herd as a lad.

But there was a more basic problem than all of these things – and you will hear about these things – as trial unfolds in the next several days. The pulsation system did not work. The vacuum lines were not consistent, and, in fact, the vacuum pumps were misplaced. Vacuum requires a balance tank, or ballast, and the ballast was not properly installed in this system at the Lokial dairy. You will hear about these problems, hear engineers talk about them, and you will see that the actual installation process varied from Westfalia’s own design criteria for the installation of its milking equipment.

These vacuum, ballast, and pulsation problems were all with the milking machine that Pulsation Int’l made and sold to the Lokials.

A More Basic Problem

But there was a more basic problem. That problem was with the carousel, the rotating platform, itself. The platform is designed to turn clockwise. It is extremely heavy – you can imagine if it will hold 60 cows, standing on a concrete platform that rotates, with milk lines and equipment, etc., and stanchions on it, it has to be heavy. In this case, the size, heaviness, and rotation were not the key problem. Instead, the problem was the stanchions where the cows were required to stand. They looked like this (holding drawing).

When the cow entered onto the carousel to be milked, it walked into a stanchion and, naturally, moved forward toward the front. This is a process the cow quickly learns. It is comfortable standing there. The carousel turns at a rate of approximately one entire rotation every 15 minutes. It does not move fast. The cow enjoys the ride.

At the back of the stanchion, where the milking is performed, a “butt rail” is installed, and, of course, extends all the way around the dairy. The butt rail is fixed. It is built on a platform separate from the stanchion so it does not rotate with it, but is placed so it holds the cow in place and prevents the cow from backing up, and falling off the stanchion during the milking process. The butt rail also provides some protection in the event a cow kicks, but not much, for the people performing the actual milking. On the carousel, forward of the butt rail, are the sides of the stanchion and some of the milking equipment. The pulsation devices, and the claws, rotate with the cow as she moves, while the butt rail is fixed.

The butt rail’s height matches the cow’s anatomy so that its height is below the top of the cow’s hips, and at about the height of her vaginal tissues. This is by design since this location will catch the cow low enough so she cannot fall out, high enough so she cannot back out off the carousel.

The butt rail, and the stanchions, were the key problem at the Lokial dairy. As one watched the cows enter onto the carousel, and then watch the carousel rotate, quickly one could see that the stanchions were too small. The problem is that the butt rail pinched against the cow, so for most of the cows – all of them but the unusually small ones – the butt rail actually rubbed, as a fixed device, up against the vaginal tissues of the cow. The cows arched their backs, and hunched up to try to get as much pressure off the butt rail, and off their sensitive tissues, as possible. The rotation around the carousel hurts. It is obvious, as you will see, while watching film of the dairy.

How did this happen? The Lokials spent hundreds of thousands of dollars for their machine. They spent millions of dollars for their cows, land, and Nebraska location. They went into business, as immigrants to our country, and used a new startup technology.

How could something so basic as a stanchion being too short have possibly happened?

Well, ladies and gentlemen, this one-inch by one-inch by 10 foot stick will probably explain it.

You see, this stick is, as you will learn from the evidence, precisely the same length as the stanchions installed by Pulsation Int’l are from the front rail, against which the cows’ front shoulders are pushed, and the butt rail.

But this blue line on the stick, about 10 inches back, represents the average length of a mature Holstein cow from the front shoulders to the back hips. The cows are longer than the stanchions. All mature American Holstein cows of average size are too big for the stanchions installed at the Lokial dairy.

How Did This Happen?

Well, it took a little investigation, but our evidence will disclose the answer. You see, Pulsation Int’l developed rotary dairies, designed them, put them in initial use, and proved they could work, in Australia and New Zealand.

And, you will learn from our expert witnesses – experts in dairy veterinary medicine, and dairy nutrition who have been to Australia and New Zealand, that the animals down under are about 10% to 15% smaller than American Holsteins. There could be many reasons – genetics and diet are most likely.

But, the problem is this, Pulsation Int’l sold the Lokials, in Nebraska, USA, North America, an Australian or New Zealand system. Its small size does not match our cows. The pain imposed on the Lokials’ cows adversely affected their milk production, caused them not to let their milk down, promoted the development of mastitis, reduced milk output, and made the cows sick. All of that has cost the Lokials about $X.X million.

We are here, ladies and gentlemen, asking you to give the Lokials back the amount of money they have lost so they can take out that improperly sized Australian or New Zealand rotary, fix the pulsation and other problems, fix the vacuum and its incorrect ballast, size their dairy to their cows, and get in business with a fresh start.

These folks want to live the American dream. They came here to operate a business and provide a product we all need. Now they need our help at getting a fresh, fair start - like they should have had from Pulsation Int’l in the beginning. Thank you.